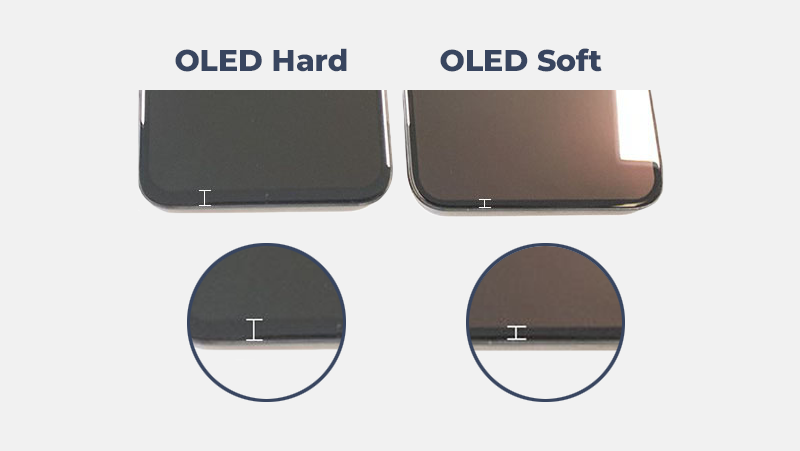

A tecnologia OLED (Diodo Orgânico Emissor de Luz) revolucionou a indústria de displays com sua qualidade de imagem superior, flexibilidade e eficiência energética. Entre os vários tipos de displays OLED, duas categorias populares são o OLED flexível (Soft OLED) e o OLED rígido (Hard OLED). Embora compartilhem uma base comum, suas diferenças em estrutura, aplicação e desempenho os tornam adequados para casos de uso distintos. Este blog explora as principais diferenças entre esses dois tipos de displays OLED.

1. Diferenças estruturais

OLED suave:

Os displays OLED flexíveis são construídos sobre substratos flexíveis, como plástico (poliimida), em vez de vidro rígido. Essa flexibilidade permite que o display dobre, enrole ou até mesmo role sem quebrar. Os componentes, incluindo as camadas orgânicas e os eletrodos, são projetados para suportar tais deformações.

OLED rígido:

Por outro lado, os displays OLED rígidos são construídos sobre substratos de vidro rígido. Essa estrutura rígida proporciona maior durabilidade contra arranhões e pressão externa, mas não permite que sejam dobrados ou flexionados.

2. Flexibilidade e Design

OLED suave:

Devido à sua natureza flexível, os displays Soft OLED são amplamente utilizados em smartphones dobráveis, dispositivos vestíveis e outras aplicações que exigem um design curvo ou adaptável. Eles possibilitam formatos inovadores e designs futuristas.

OLED rígido:

Os displays OLED rígidos têm um design mais tradicional, sendo planos e inflexíveis. São comumente usados em smartphones, TVs, monitores e outros dispositivos onde uma tela rígida é suficiente.

3. Espessura e Peso

OLED suave:

Os OLEDs flexíveis são geralmente mais finos e leves do que seus equivalentes rígidos devido ao substrato plástico. Essa característica é particularmente vantajosa para dispositivos portáteis e vestíveis, onde peso e tamanho são fatores críticos.

OLED rígido:

Embora sejam ligeiramente mais espessos e pesados devido ao substrato de vidro, os OLEDs rígidos ainda oferecem um formato compacto em comparação com as tecnologias LCD mais antigas. No entanto, são menos adequados para aplicações em que um design leve é uma prioridade.

4. Durabilidade e robustez

OLED suave:

O substrato plástico dos OLEDs flexíveis os torna menos propensos a quebrar em comparação com telas de vidro. No entanto, eles podem ser mais suscetíveis a arranhões e podem exigir camadas protetoras adicionais para garantir sua durabilidade.

OLED rígido:

As telas OLED rígidas são altamente resistentes a arranhões, mas podem quebrar com o impacto devido à fragilidade do vidro. Capas protetoras ou películas de proteção são frequentemente necessárias para aumentar a durabilidade em dispositivos com telas OLED rígidas.

5. Custo e Fabricação

OLED suave:

O processo de produção de OLEDs flexíveis é mais complexo e requer materiais e técnicas de fabricação avançadas, resultando em custos mais elevados. Essa é uma das razões pelas quais dispositivos com telas OLED flexíveis, como celulares dobráveis, costumam ser mais caros.

OLED rígido:

Os OLEDs rígidos são mais baratos de fabricar devido ao seu processo de produção mais simples e à ampla disponibilidade de substratos de vidro. Isso os torna uma opção economicamente viável para muitos dispositivos eletrônicos de consumo.

6. Casos de uso e aplicações

| Recurso | OLED suave | OLED rígido |

|---|---|---|

| Flexibilidade | Designs dobráveis, enroláveis e adaptáveis | designs planos e rígidos |

| Durabilidade | Resistente a estilhaços; propenso a arranhões. | Resistente a riscos; propenso a quebrar. |

| Custo | Custo de fabricação mais elevado | Mais acessível de produzir |

| Aplicações típicas | Telefones dobráveis, dispositivos vestíveis, telas curvas | TVs, monitores, smartphones padrão |

Conclusão

As tecnologias OLED flexíveis e OLED rígidas possuem vantagens e limitações específicas. O OLED flexível se destaca em aplicações que exigem flexibilidade e formatos inovadores, enquanto o OLED rígido é ideal para designs tradicionais de tela plana, onde custo-benefício e resistência a arranhões são prioridades. Compreender essas diferenças pode ajudar consumidores e fabricantes a tomar decisões mais informadas na escolha da tecnologia de tela mais adequada às suas necessidades.

Com a evolução contínua da tecnologia OLED, podemos esperar novas inovações que irão diluir as fronteiras entre telas flexíveis e rígidas, abrindo caminho para dispositivos mais versáteis e duráveis.